Pressure: 4.8MPa or higher

-

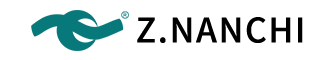

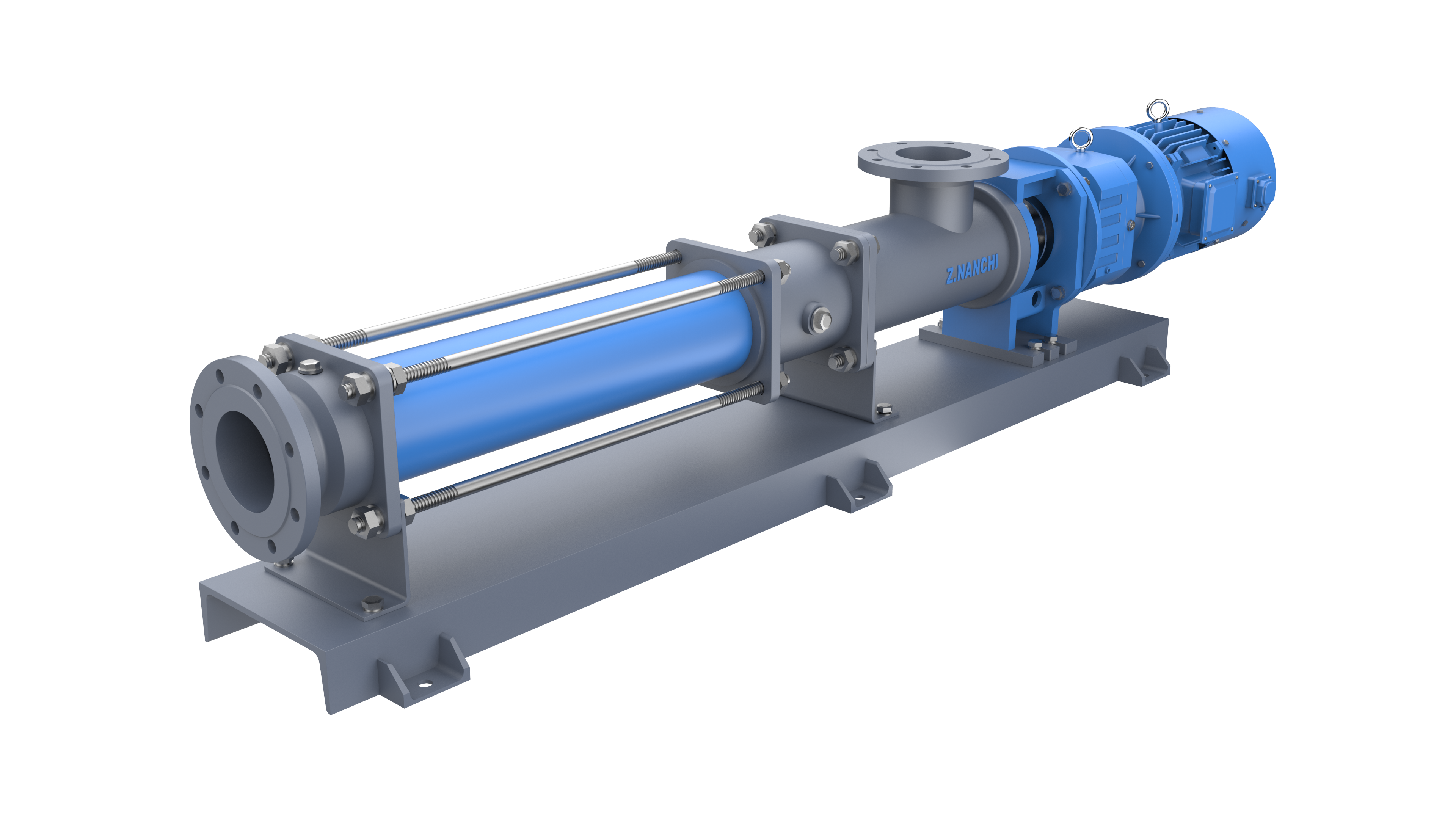

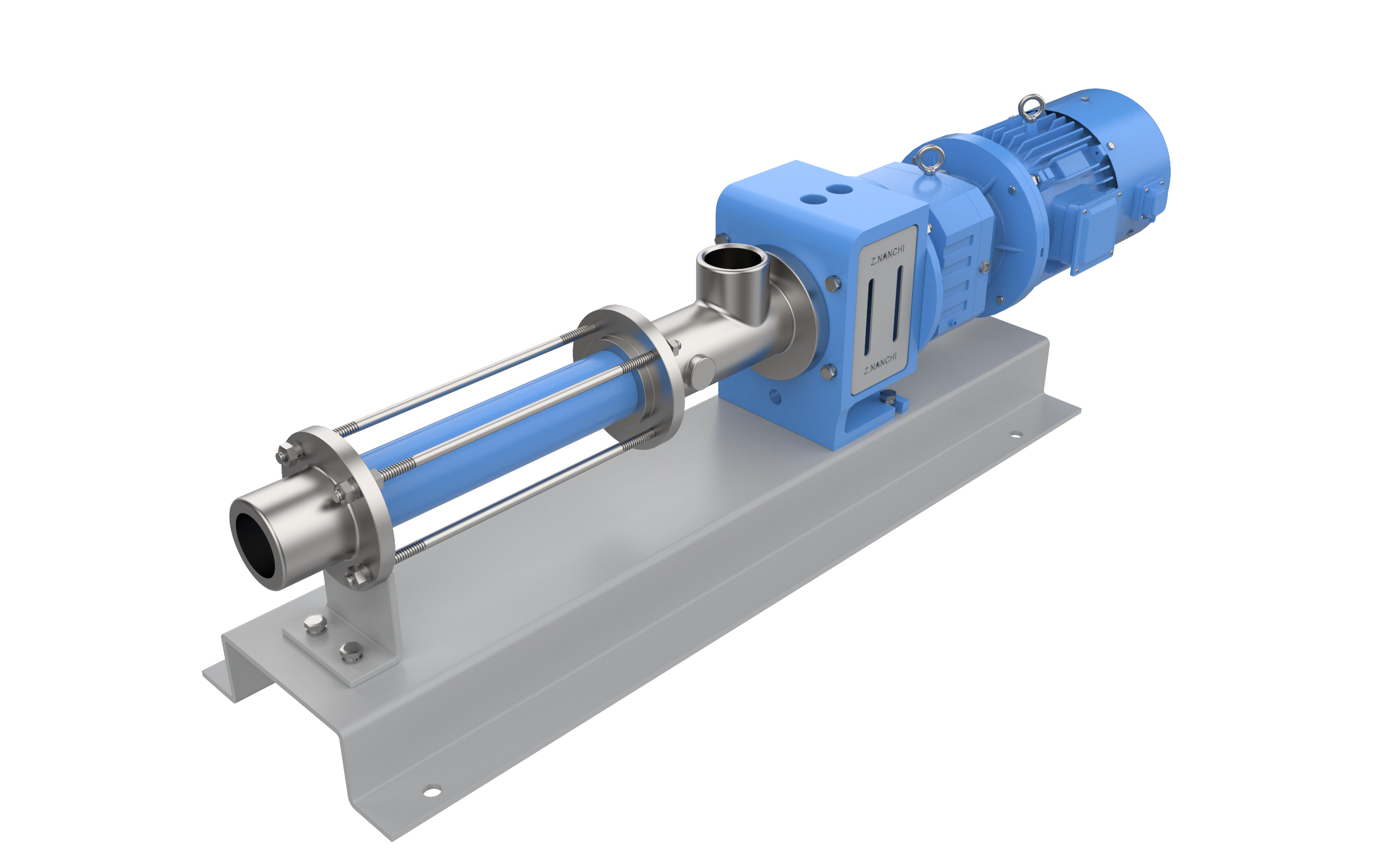

NG Standard Single Screw PumpCapacity: 0.1m3/h ~ 500m3/h

NG Standard Single Screw PumpCapacity: 0.1m3/h ~ 500m3/h

Pressure: 4.8MPa or higher

-

NS Mixing Feed PumpCapacity: 0.1m3/h ~ 400m3/h

NS Mixing Feed PumpCapacity: 0.1m3/h ~ 400m3/h

Pressure: 4.8MPa or higher

-

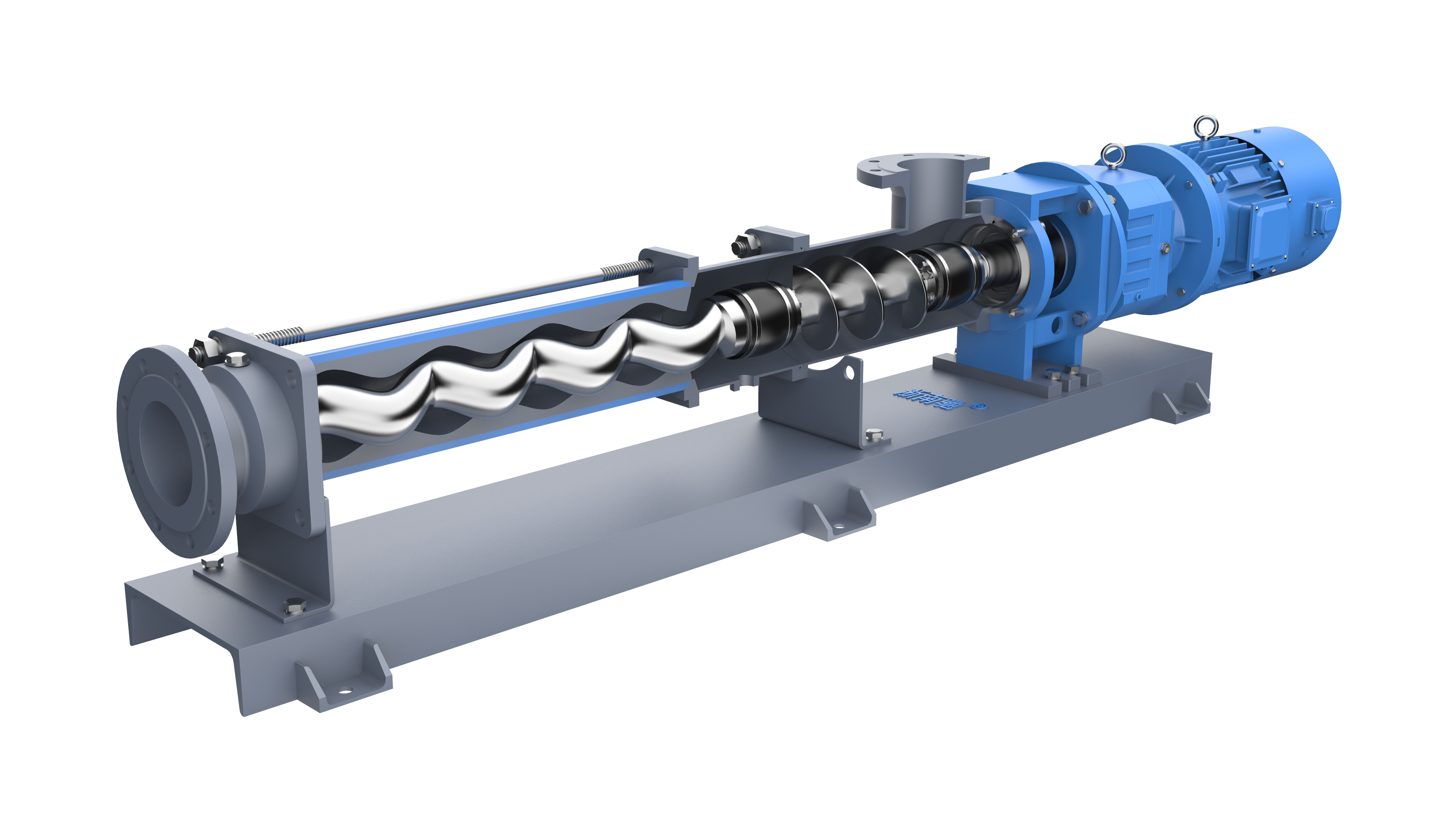

NH Food Hygienic PumpCapacity: 0.1m3/h ~ 200m3/h

NH Food Hygienic PumpCapacity: 0.1m3/h ~ 200m3/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

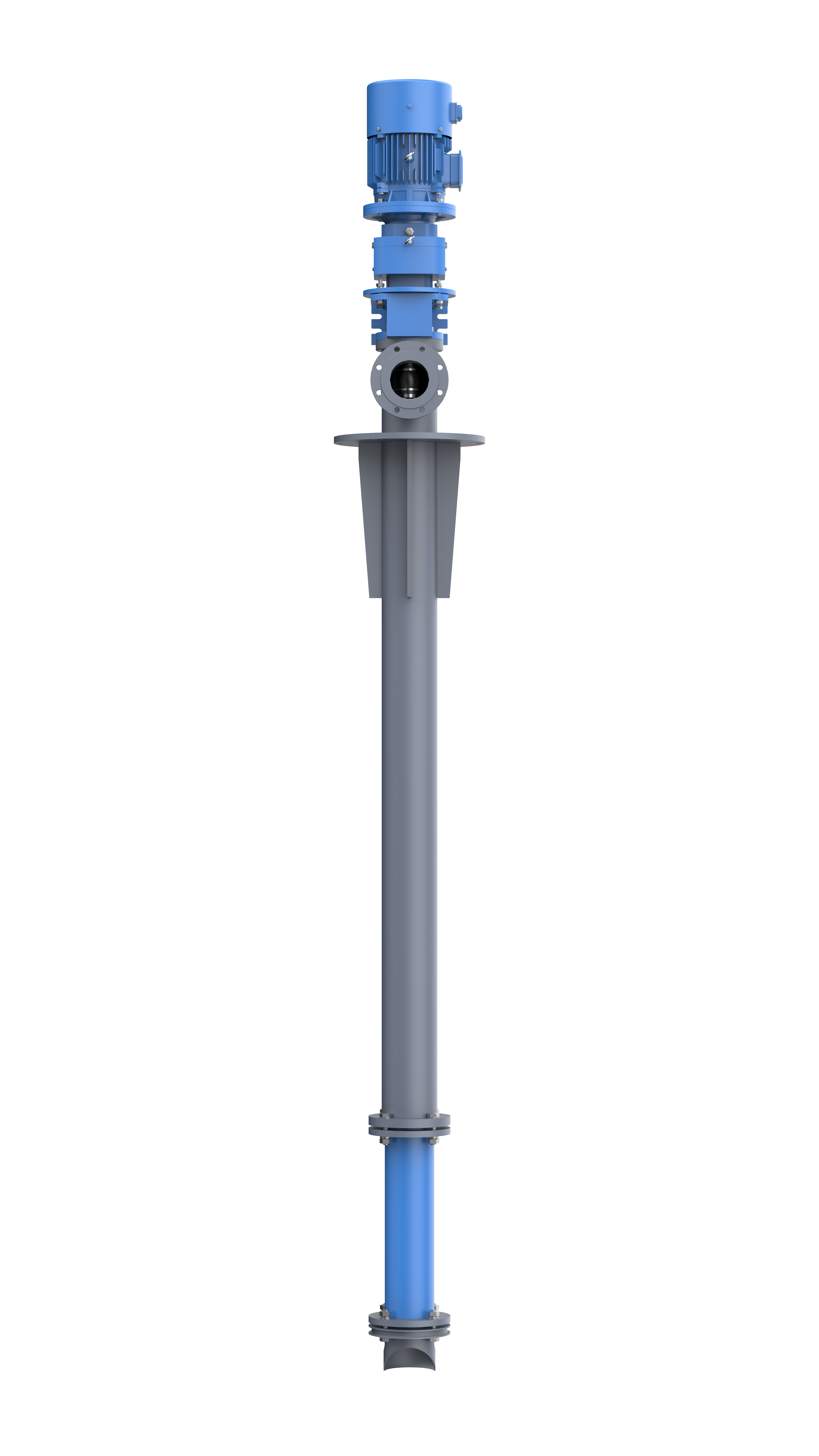

NV Vertical PumpCapacity: 0.1m3/h ~ 100m3/h

NV Vertical PumpCapacity: 0.1m3/h ~ 100m3/h

Pressure: 1.2MPa or higher

The water source will determine the amount of pollution and the required level of treatment. For example, the overall pollution of well fluids may be less than that of river or reservoir water, but nitrate removal treatment may be required. River water usually contains the most impurities, so it requires the most treatment. The reservoir water is cleaner, but it still needs to be treated. The principle is usually the same, and Nanchi's pump series has flexibility and can meet the following different needs:

- Remove physical sediment, as well as biological and chemical pollutants

- Adjusting the pH value by adding acid or alkali

- Disinfect by adding chlorine based compounds before delivery

Solution

Some sample applications are as follows:

- NP series for flocculant dosage determination

- NG series with intelligent conveying technology for sludge feeding and transportation

- NT series for dewatering sludge

- NP or NG series for pH adjustment

- NP or NG series for disinfection of Hypochlorite dosimetry

- Intelligent metering pump and vertical Screw pump optimize chemical consumption

- Control system for intelligent metering or filter press filling

- Intelligent conveying technology

Z.NANCHI is a professional single screw pump manufacturer. It has its own application project plan in water purification engineering. Please contact us if necessary.

Use various chemicals during the treatment of drinking water to improve water quality. Each water source is different, so each municipality must find the best combination of chemicals for water treatment.

Solution

Z.NANCHI pump, single screw pump and vertical screw pump are used to accurately measure chemicals required in each treatment step. Z.NANCHI engineers will match the chemical compatibility of all wetted components with the characteristics of the chemicals to be transported.

- NSF Standard 61 and WRAS certified.

- Low pulsation - no pulsation buffer required

- No steam blockage phenomenon

- Check valves do not require cleaning or replacement accurate and repeatable processes.

- Single screw pump self-priming.

- Screw pump, control device meeting individual needs