Pressure: 4.8MPa or higher

-

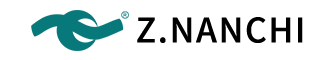

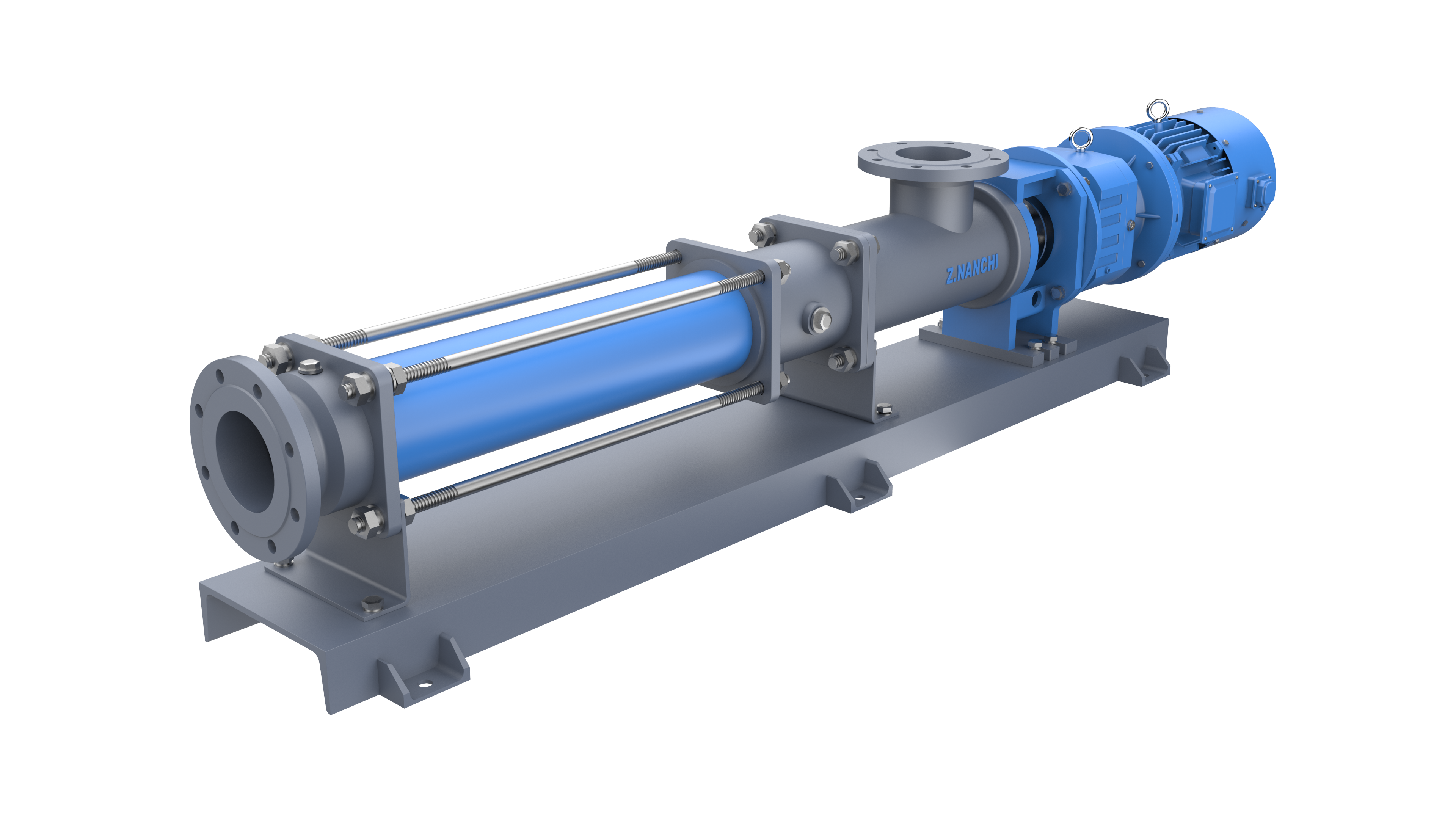

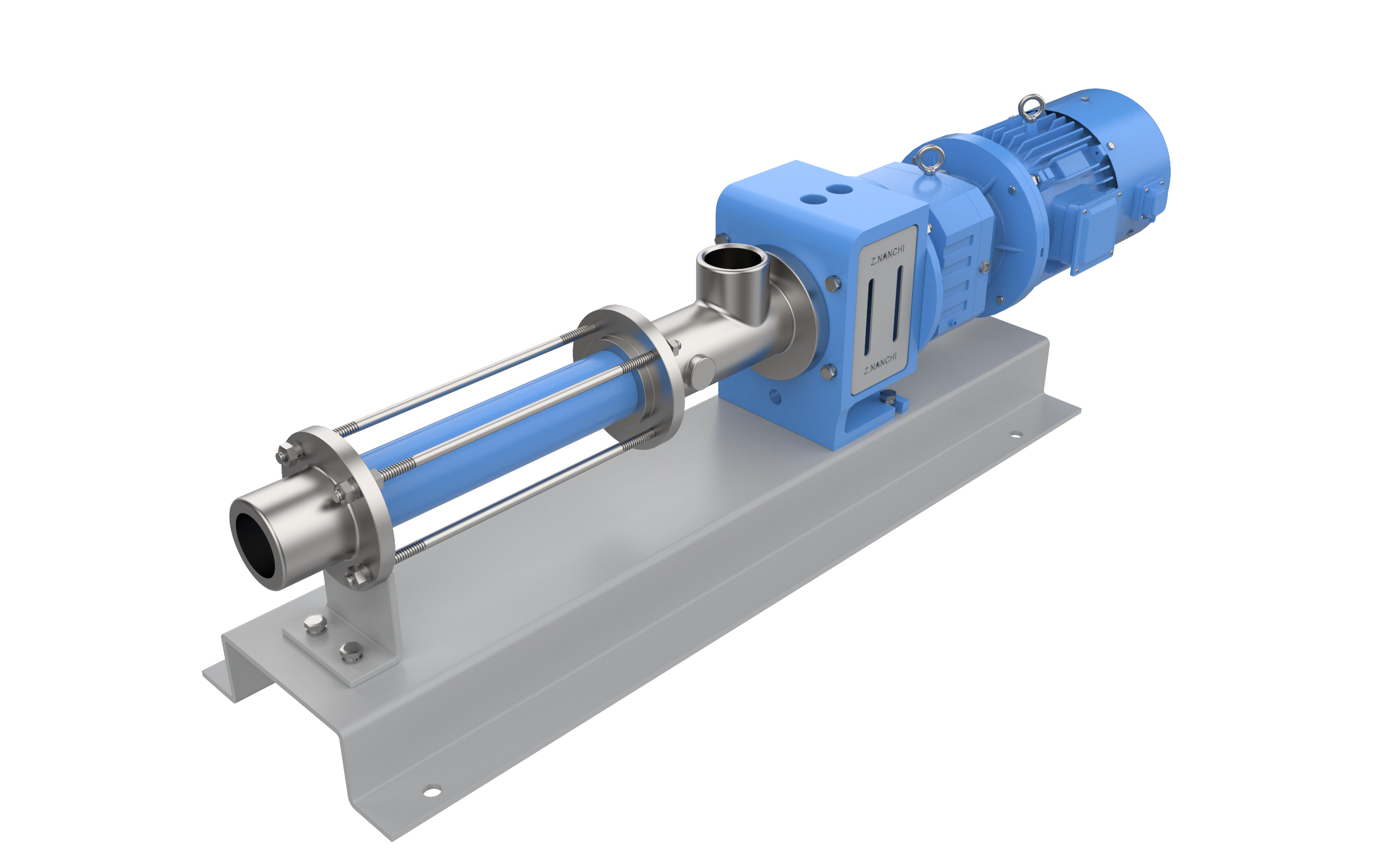

NG Standard Single Screw PumpCapacity: 0.1m3/h ~ 500m3/h

NG Standard Single Screw PumpCapacity: 0.1m3/h ~ 500m3/h

Pressure: 4.8MPa or higher

-

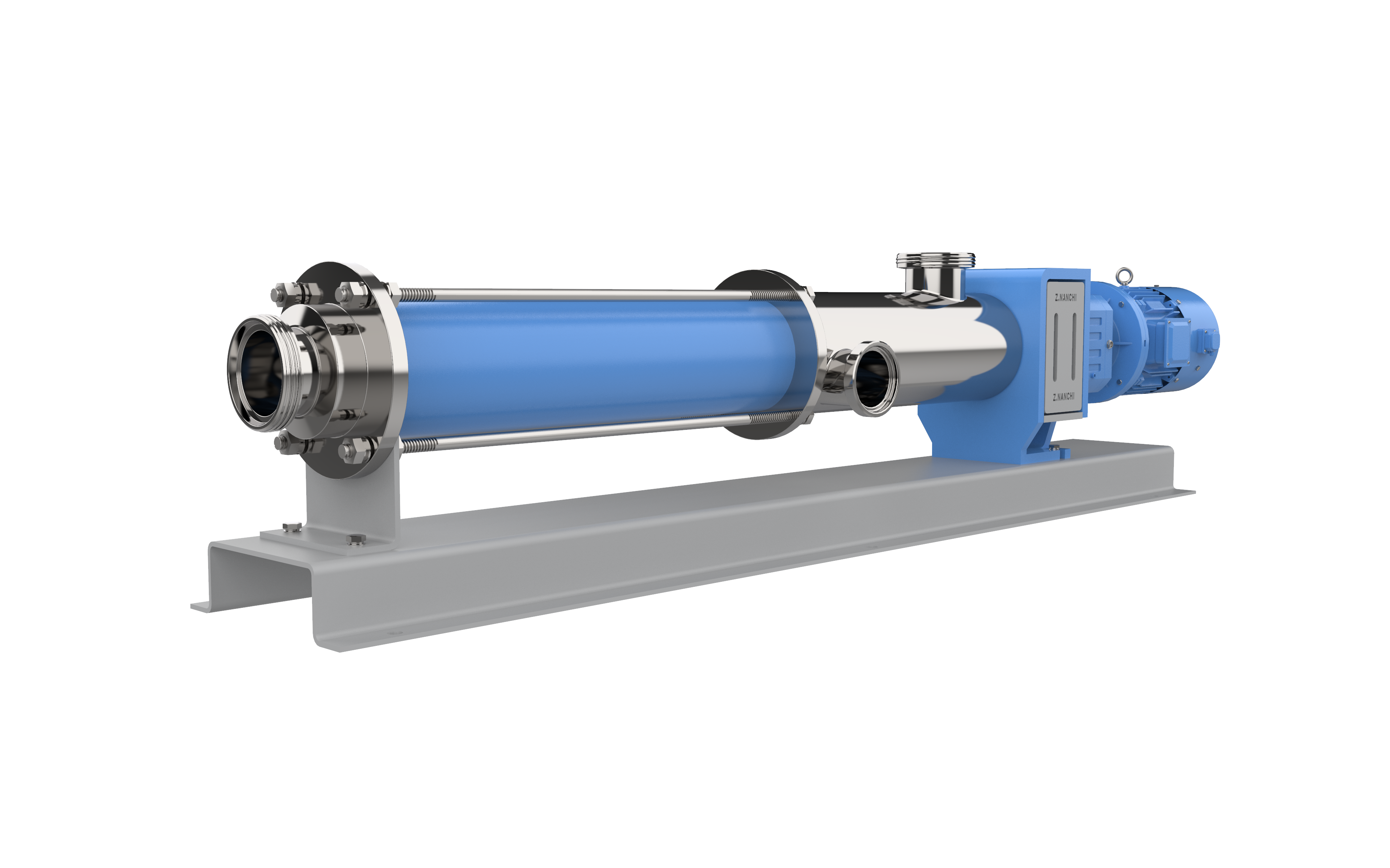

NS Mixing Feed PumpCapacity: 0.1m3/h ~ 400m3/h

NS Mixing Feed PumpCapacity: 0.1m3/h ~ 400m3/h

Pressure: 4.8MPa or higher

-

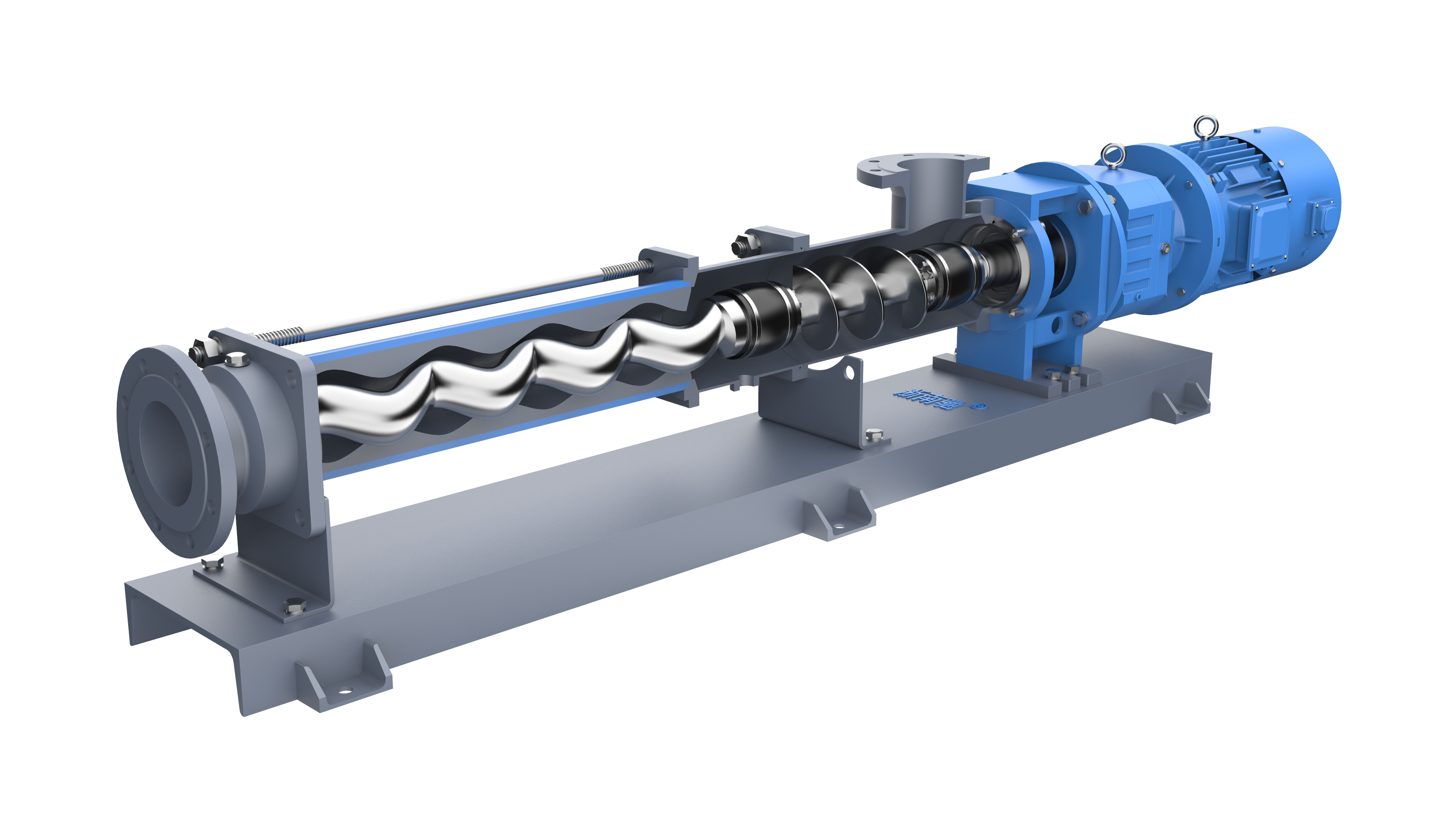

NH Food Hygienic PumpCapacity: 0.1m3/h ~ 200m3/h

NH Food Hygienic PumpCapacity: 0.1m3/h ~ 200m3/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

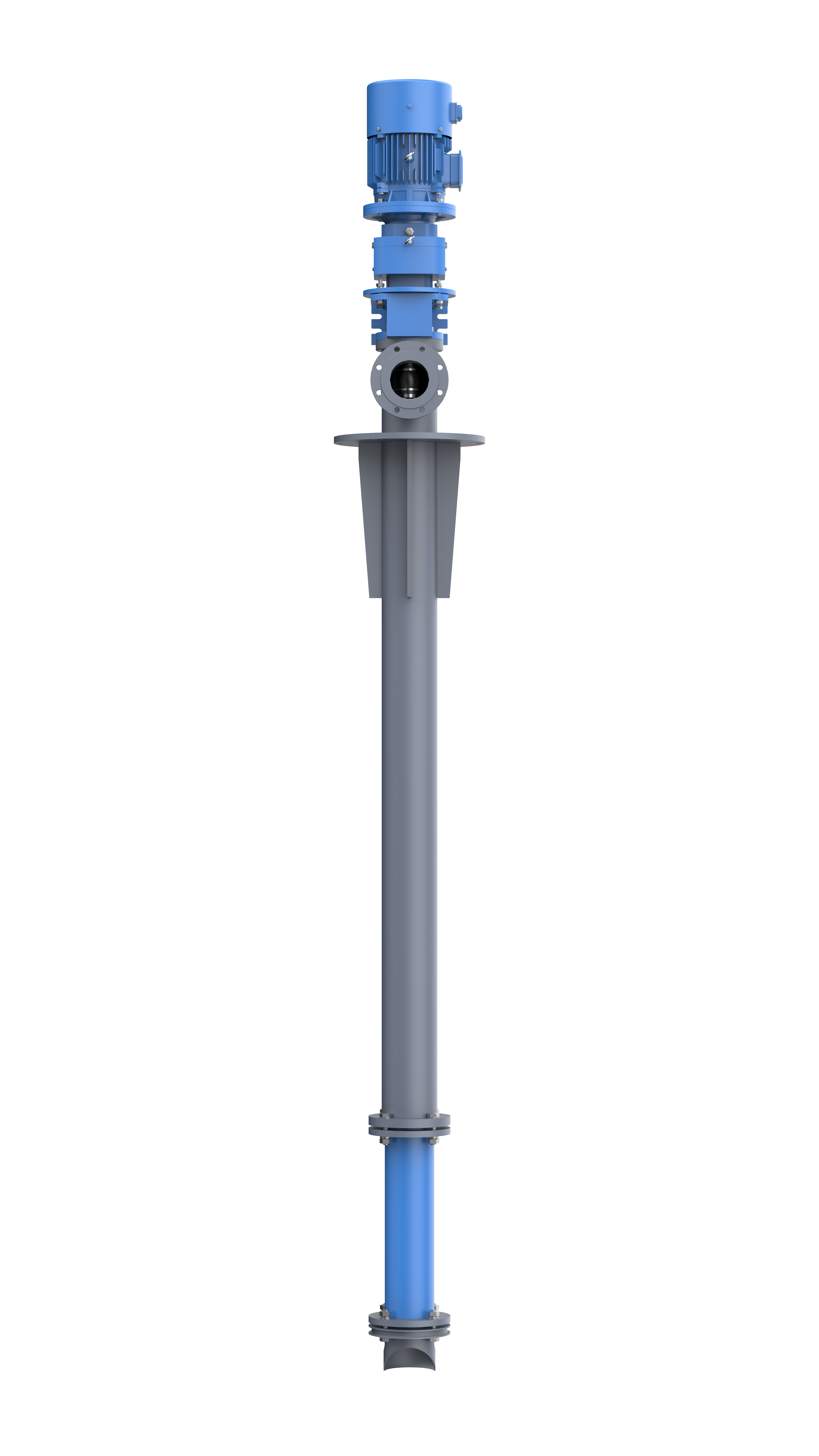

NV Vertical PumpCapacity: 0.1m3/h ~ 100m3/h

NV Vertical PumpCapacity: 0.1m3/h ~ 100m3/h

Pressure: 1.2MPa or higher

The single screw pump is a positive displacement pump, its rotor is made of stainless steel or 40 chrome, and its stator is made of medium hardness rubber, so it is very suitable for conveying solid particles and thicker media, such as sludge and sewage treatment. For example:

- Transport soybean residue, sugar juice, scum, and beet residue at the sugar factory.

- Fill and transport milk powder, starch, honey, coffee, milk, butter, edible oil, various vitamin solutions, Maltose, ketchup, jam, Mayonnaise, ice cream, etc. in canning plants and food factories.

- Provide alcoholic beverages, spices, fermented liquid ingredients at the brewery, and transport food residue through a filter press.

- Transport Cod liver oil, fish oil, fish line and fish dregs in the fish processing plant.

- Transport sugar and juice at fruit processing plants, crush oranges and fruits, and feed filling machines.

- Filling and transporting edible oil, rice and Corn starch in grain and oil processing plants.

- Meat processing plants and slaughterhouses, extraction, packaging, and transportation of fats and meat oils.

- Pharmaceutical factory: Supply and transport various vitamin solutions, chemicals, emulsions, suspensions, saltwater, salt sludge, drug residues, etc.

- Chemical industry: transportation of acids and rye, different suspensions, oils, adhesives, different chemical dyes, coatings, different adhesives, ointments, slurries, especially common centrifugal consumables, batch processing. This pump can transport various high viscosity materials, solid particles, and materials that cannot be transported by transport pumps.

- Ink is transported in batches.

- Transport pulp and ink in Paper mill.

- Transportation of petroleum products, fats, and wastewater sludge in petrochemical plants.

- Transport carbide slag from the acetylene station.

- Transportation of mortar, lime milk, mortar, cement slurry, etc. in the construction industry.

- It can be used for pumping, transportation, and equipment during feed processing.

- Widely used for industrial and household sewage and sludge treatment. The content of corrosive, viscous Suspended solids in sewage is usually very high, and often contains solid particles. It is appropriate to use a thick slurry pump for solids.

- Used for transporting contaminated water, contaminated liquids, and other substances in nuclear power plants.

- Mine sewage and sludge.

For more information about screw pump or single screw pump manufacturer, please consult Z.NANCHI pump!

Generally, single screw pump is widely used. For sludge screw pump, it is very suitable for conveying solid particles and thicker media, such as sludge and sewage treatment.

Startip procedure of sludge screw pump:

- Prepare necessary wrenches and tools.

- Ensure that the machine seat, bearings, and oil chamber are free of lubricating oil.

- Check if the air tightness of the hollow shaft is suitable. Do not push the packing disc too hard, causing it to seep out like dripping water.

- Rotate the coupling by hand or with a pipe wrench, pay attention to the sound of foreign objects colliding and jamming on the pump body, and remove them before operation.

- Fill the pump cavity with material and do not rub it to avoid spikes in the bushing.

- Fully open the gate valve of the liquid outlet pipe.

- Turn on the motor power.

Z.NANCHI pump is a professional manufacturer of single screw pump. Welcome to your consultation!