Pressure: 4.8MPa or higher

-

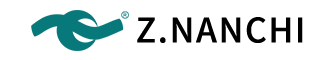

NG Standard Single Screw PumpCapacity: 0.1m3/h ~ 500m3/h

NG Standard Single Screw PumpCapacity: 0.1m3/h ~ 500m3/h

Pressure: 4.8MPa or higher

-

NS Mixing Feed PumpCapacity: 0.1m3/h ~ 400m3/h

NS Mixing Feed PumpCapacity: 0.1m3/h ~ 400m3/h

Pressure: 4.8MPa or higher

-

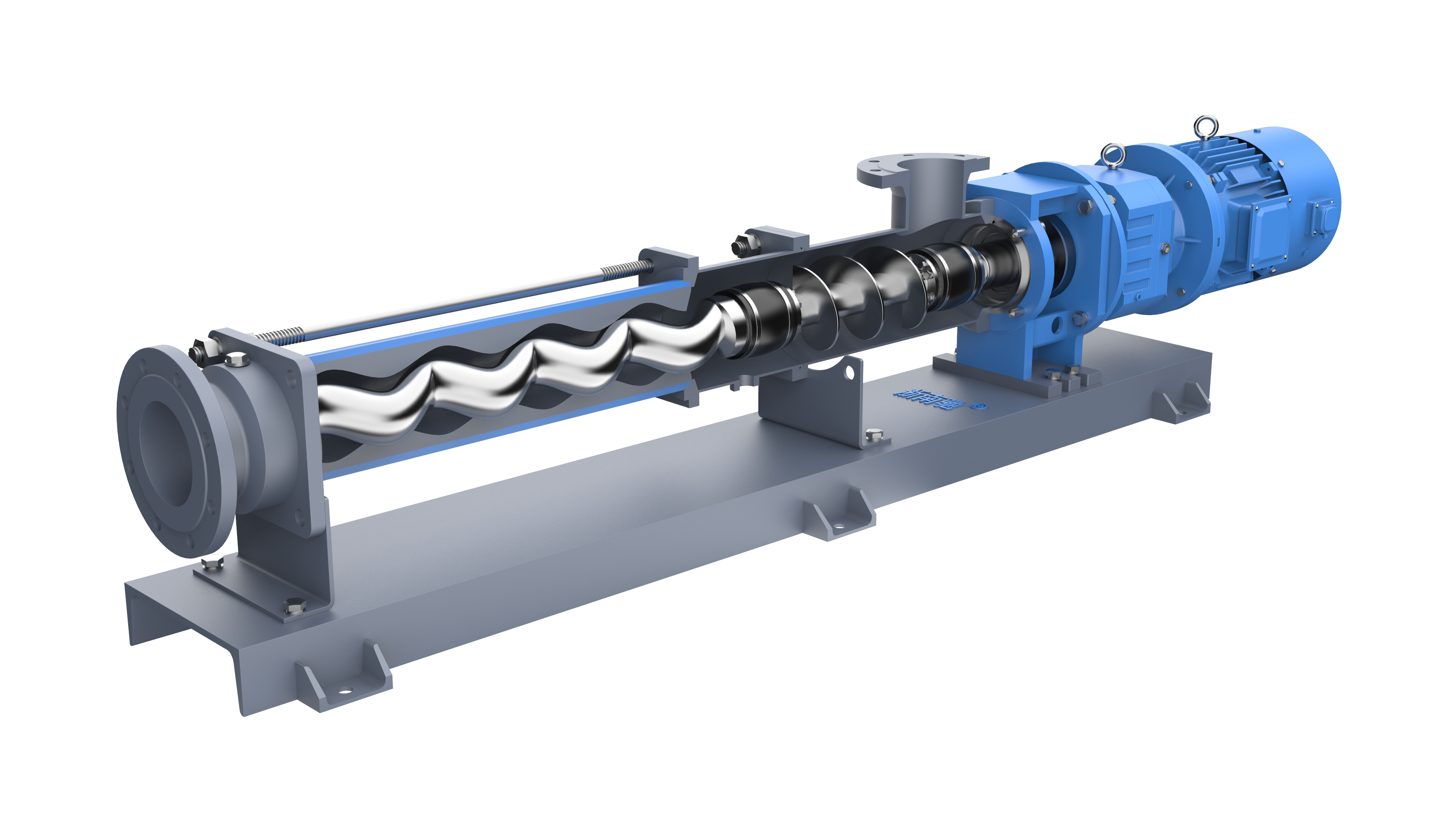

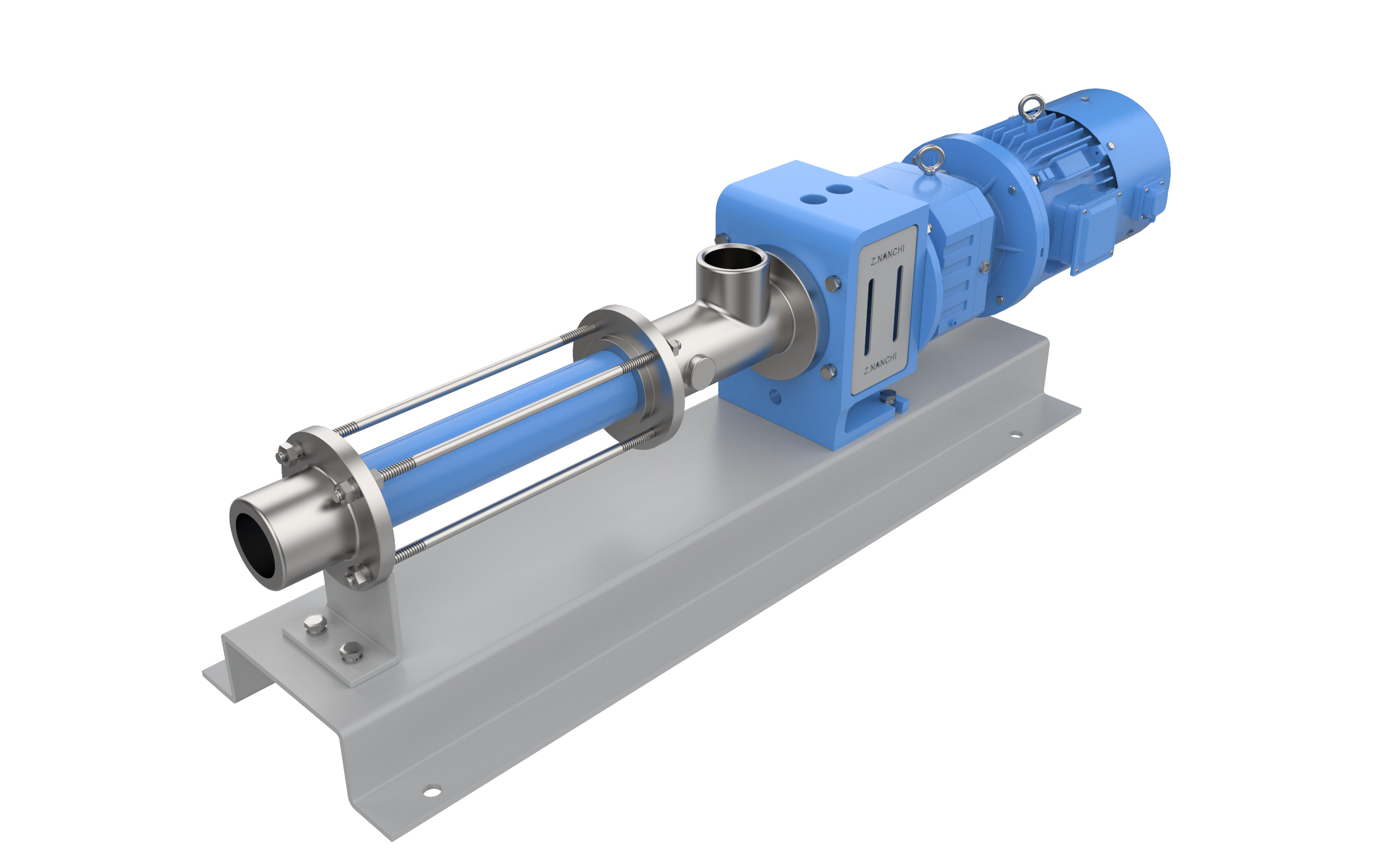

NH Food Hygienic PumpCapacity: 0.1m3/h ~ 200m3/h

NH Food Hygienic PumpCapacity: 0.1m3/h ~ 200m3/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

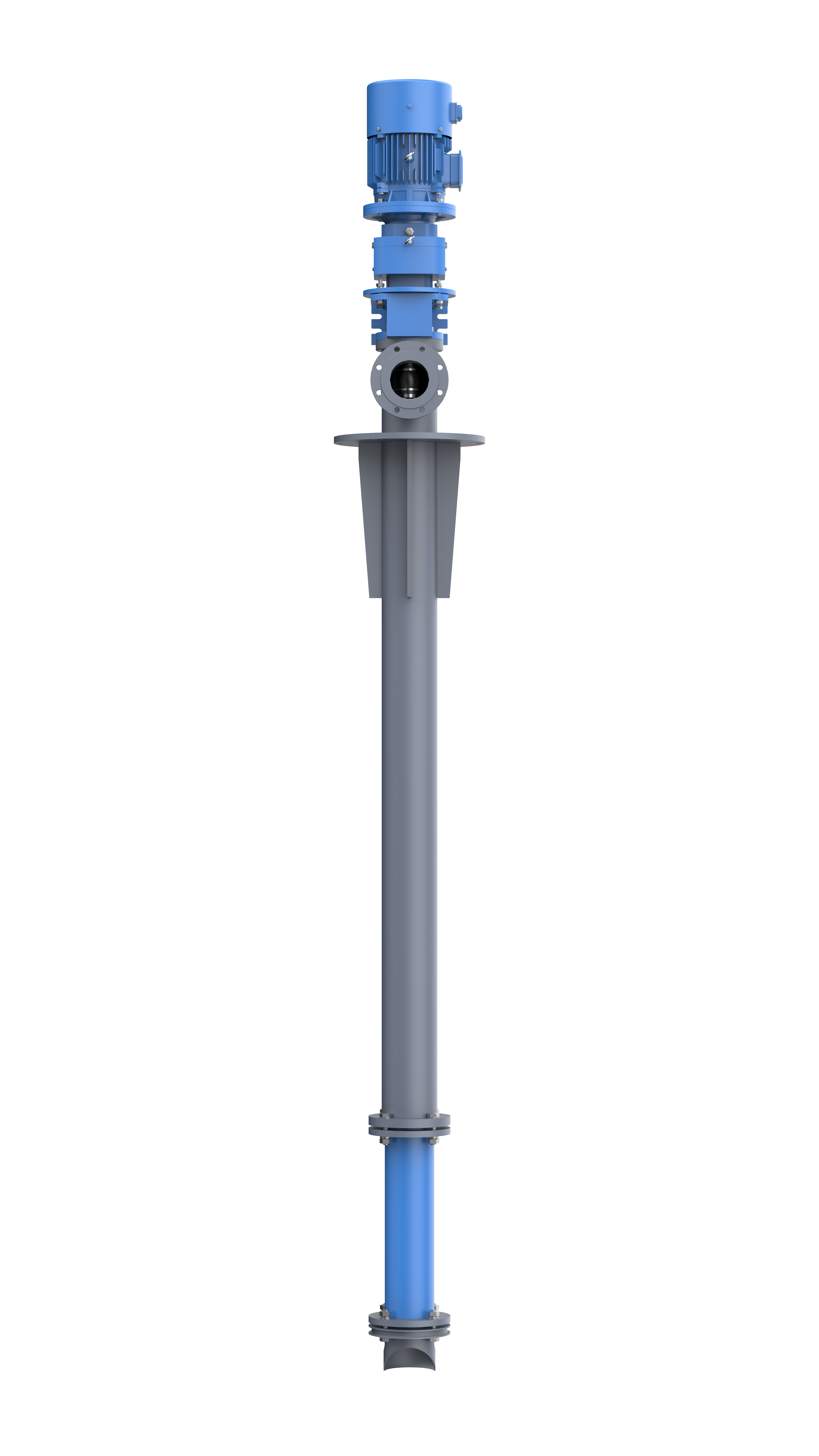

NV Vertical PumpCapacity: 0.1m3/h ~ 100m3/h

NV Vertical PumpCapacity: 0.1m3/h ~ 100m3/h

Pressure: 1.2MPa or higher

Focuses on the development, manufacturing, sales and technical services of screw pump and single screw pump. Advanced CNC processing equipment and scientific management mode are adopted to create high-quality screw pump products. Smooth transportation of high viscosity, corrosive or abrasive media in complex systems.

Our products

There are nine series and hundreds of screw pump products created by Z.NANCHI which are widely used in almost all industries. Used to transport all flowing materials, even high viscosity, high solid content, non flowing materials. The flow rate covers 0.02 l/min to 600 m3/h, and the pressure reaches 4.8Mpa or higher. It is one of the screw pump manufacturers with the most complete serial models in China.

Our screw pump technology

Z.NANCHI screw pump has no pulse and minimal shearing effect. It is suitable for applications where the flow is required to be stable and does not change with the product viscosity or pressure. Compared to other volumetric pumps, their working pressure is higher.

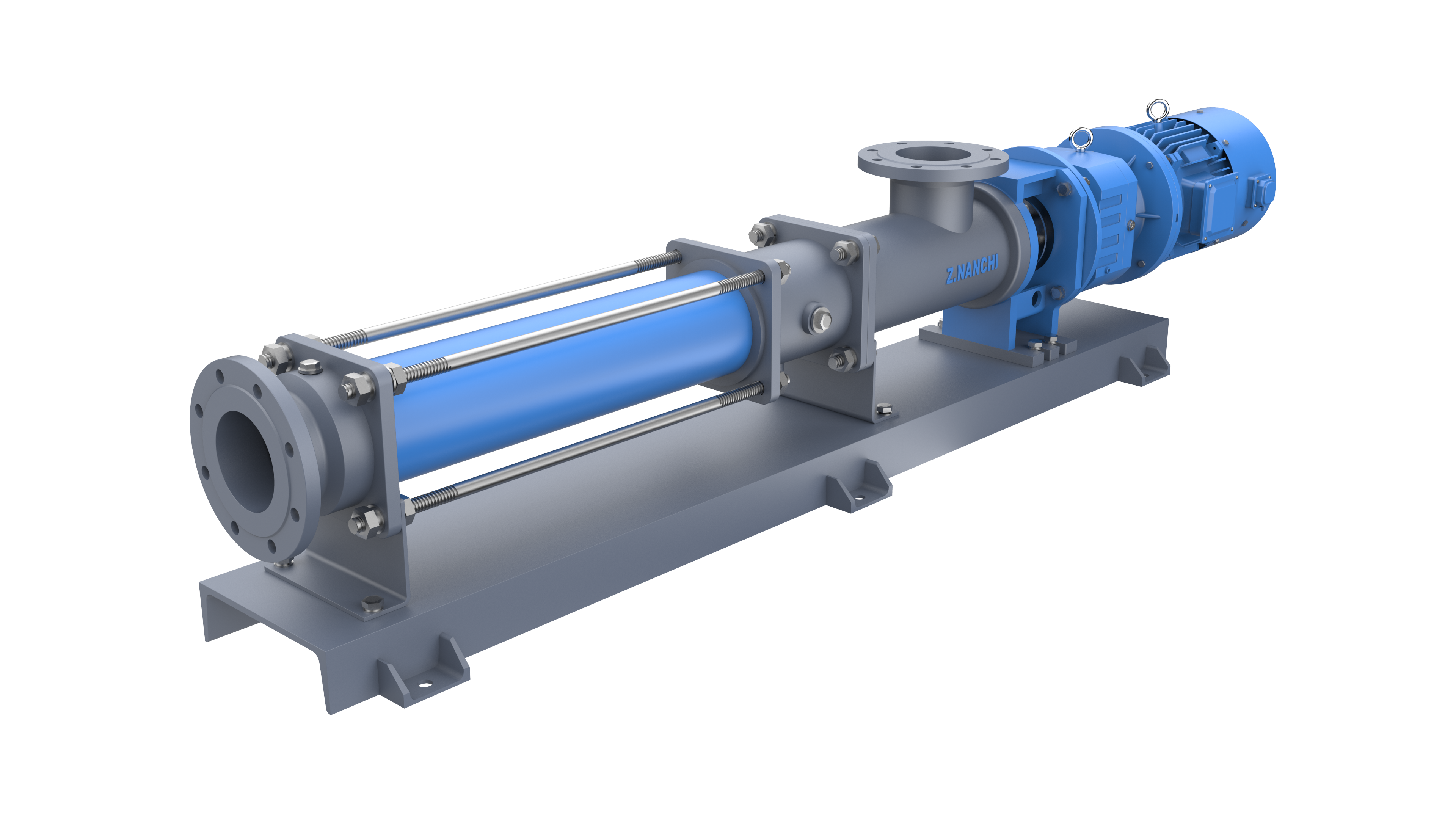

Working principle of our screw pump

The main body of Z.NANCHI screw pump is spiral rotor and stator. The rotor is finely machined from various metal materials, while the stator is molded from elastic rubber. Due to the special shape and size design, when the rotor is inserted into the stator, a honeycomb shaped enclosed space is formed. When the rotor rotates inside the stator, the enclosed space spirals along the pump axis, and the shape and volume do not change. This process transports the product from the inlet end of the pump to the outlet end of the pump. By using this transportation method, the quality of the product will not decrease from the pump inlet to the outlet.

Our solution

The technical department of Z.NANCHI can provide consulting services for fluid transportation, which is not just about recommending pump types for us. Providing solutions for fluid transportation to help customers achieve success is the meaning of our services, and how can we pioneer the development of solutions? Based on our successful experience, the key is to have a deep understanding of customers and close cooperation with them, helping them optimize their systems, improve production efficiency, and also reduce operational costs.